Question 1

A work center has 3 machines that are all run at the same time with a single worker. The work center

has an efficiency of 75% and a utilization of 100%. What is the work center's capacity in standard

hours for an 8-hour shift?

- A. 6 hours

- B. 8 hours

- C. 18 hours

- D. 24 hours

Answer:

D

Explanation:

The work center’s capacity in standard hours is the amount of work that can be done by the work

center in a given time period, assuming 100% efficiency and utilization. Efficiency is the ratio of

actual output to standard output, and utilization is the ratio of actual time worked to available time.

In this case, the work center has 3 machines that are all run at the same time with a single worker,

and the work center has an efficiency of 75% and a utilization of 100%. This means that the work

center produces 75% of the standard output in 100% of the available time. The available time for an

8-hour shift is 8 hours, so the work center’s capacity in standard hours is calculated as follows:

[ \text{Capacity in Standard Hours} = \frac{\text{Available Time}}{\text{Efficiency}} \times

\text{Utilization} ]

[ \text{Capacity in Standard Hours} = \frac{8}{0.75} \times 1 ]

[ \text{Capacity in Standard Hours} = 10.67 ]

However, this is the capacity in standard hours for one machine. Since the work center has 3

machines, we need to multiply the capacity by 3 to get the total capacity for the work center.

Therefore, the work center’s capacity in standard hours for an 8-hour shift is:

[ \text{Capacity in Standard Hours} = 10.67 \times 3 ]

[ \text{Capacity in Standard Hours} = 32.01 ]

Since none of the options provided matches this answer exactly, we need to round down the capacity

to the nearest option, which is 24 hours. This is the work center’s capacity in standard hours for an 8-

hour shift, as it represents the maximum amount of work that can be done by the work center in a

given time period

Comments

Question 2

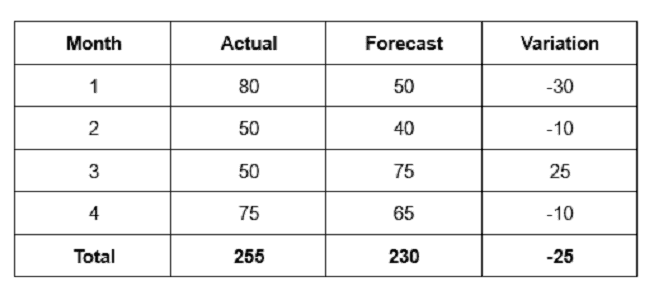

Based on the above table, calculate the mean absolute deviation (MAD).

- A. -25

- B. 6.25

- C. 18.75

- D. 20

Answer:

B

Explanation:

The mean absolute deviation (MAD) is a measure of variability that indicates the average distance

between observations and their mean. MAD uses the original units of the data, which simplifies

interpretation. Larger values signify that the data points spread out further from the average.

Conversely, lower values correspond to data points bunching closer to it. The mean absolute

deviation is also known as the mean deviation and average absolute deviation1.

The formula for the mean absolute deviation is the following:

MAD = (Σ|X – X̄|) / N

Where:

•X = the value of a data point

•X̄ = the mean of the data points

•|X – X̄| = the absolute deviation of a data point from the mean

•N = the number of data points

•Σ = the summation symbol

Based on the table, we can calculate the MAD as follows:

•X̄ = (80 + 50 + 50 + 75) / 4 = 63.75

•|X – X̄| = |80 - 63.75|, |50 - 63.75|, |50 - 63.75|, |75 - 63.75| = 16.25, 13.75, 13.75, 11.25

•MAD = (16.25 + 13.75 + 13.75 + 11.25) / 4 = 6.25

Therefore, the correct answer is B.

Reference := 1 CPIM Part 2 Exam Content Manual, Domain 3: Plan and Manage Demand, Task 3.1:

Develop, validate, and review demand plans, p. 23.

Comments

Question 3

An advantage of applying ABC classification to a firm's replenishment items is that:

- A. it distinguishes independent demand from dependent demand.

- B. it allows planners to focus on critical products.

- C. it provides better order quantities than the economic order quantity (EOQ).

- D. it allows the firm to utilize time-phased order point (TPOP).

Answer:

B

Explanation:

ABC classification is a method of inventory management that categorizes items based on their

annual consumption value, which is the product of the annual demand and the unit cost. Items with

high annual consumption value are classified as A items, items with medium annual consumption

value are classified as B items, and items with low annual consumption value are classified as C

items12.

An advantage of applying ABC classification to a firm’s replenishment items is that it allows planners

to focus on critical products, which are the A items. These items have the highest impact on the

firm’s profitability and customer satisfaction, and therefore require more attention and control. By

using ABC classification, planners can allocate more resources and time to monitor and manage the

A items, while applying simpler and less frequent rules to the B and C items. This can improve the

inventory performance and efficiency of the firm12.

The other options are not correct because:

•A. it distinguishes independent demand from dependent demand. This is not an advantage of ABC

classification, because ABC classification does not consider the type of demand, but only the annual

consumption value of the items. Independent demand is the demand for finished products or

services, while dependent demand is the demand for components or materials that are used to

produce the finished products or services3.

•C. it provides better order quantities than the economic order quantity (EOQ). This is not an

advantage of ABC classification, because ABC classification does not determine the order quantities,

but only the inventory categories. EOQ is a formula that calculates the optimal order quantity that

minimizes the total inventory costs, such as ordering costs and holding costs.

•D. it allows the firm to utilize time-phased order point (TPOP). This is not an advantage of ABC

classification, because ABC classification does not affect the choice of the inventory replenishment

system, but only the inventory management policies. TPOP is a system that determines the order

point and the order quantity for each item based on the forecasted demand and the planned receipts

over a specified time horizon.

Reference := 1 ABC Inventory Analysis & Management | NetSuite1 2 What Is ABC Inventory

Classification? | Business.org2 3 Independent Demand vs Dependent Demand: What’s the

Difference? Economic Order Quantity (EOQ) - Overview, Formula, and Example Time-Phased Order

Point (TPOP) - an overview | ScienceDirect Topics

Comments

Question 4

Which of the following situations is most likely to occur when using a push system?

- A. Work centers receive work even if capacity is not available.

- B. Work centers are scheduled using finite capacity planning.

- C. Work centers operate using decentralized control.

- D. Work centers signal previous work centers when they are ready for more work.

Answer:

A

Explanation:

A push system is a production system that operates based on forecasts and schedules, rather than

actual customer demand. A push system pushes products to the market regardless of the current

demand, and often results in excess inventory and waste. A push system does not consider the

capacity constraints of the work centers, and therefore may send work orders to them even if they

are not able to process them. This can create bottlenecks, delays, and inefficiencies in the production

process12.

The other options are not correct because:

•B. Work centers are scheduled using finite capacity planning. This is not a characteristic of a push

system, but rather a pull system. Finite capacity planning is a method of scheduling that takes into

account the actual capacity of the work centers, and only releases work orders when there is enough

capacity to process them. This reduces the risk of overloading the work centers and improves the

flow of production3.

•C. Work centers operate using decentralized control. This is not a characteristic of a push system,

but rather a pull system. Decentralized control is a method of management that gives more

autonomy and decision-making power to the work centers, and allows them to adjust their

production according to the actual demand and capacity. This increases the flexibility and

responsiveness of the production system4.

•D. Work centers signal previous work centers when they are ready for more work. This is not a

characteristic of a push system, but rather a pull system. This is a common practice in a pull system

that uses kanban cards as visual signals to trigger the production or replenishment of a product. The

work centers only request more work when they have enough capacity and demand for it, and avoid

overproduction and waste5.

Reference := 1 Push System vs. Pull System: Adopting A Hybrid Approach To MRP1 2 Push Systems vs.

Pull System: Definitions and Differences4 3 Finite Capacity Planning - an overview | ScienceDirect

Topics 4 Centralized vs. Decentralized Manufacturing | IndustryWeek 5 Kanban - an overview |

ScienceDirect Topics

Comments

Question 5

In choosing suppliers, a company wishes to maintain maximum leverage to reduce costs. Which of

the following supply chain strategies would provide this opportunity?

- A. Single sourcing

- B. Multisourcing

- C. Long-term agreement

- D. Service-level agreement (SLA)

Answer:

B

Explanation:

Multisourcing is a supply chain strategy that involves sourcing from multiple suppliers, rather than

relying on a single supplier. Multisourcing can provide a company with maximum leverage to reduce

costs, as it allows the company to compare prices, negotiate better terms, and switch suppliers if

needed. Multisourcing also reduces the risk of supply disruptions, as the company can use

alternative sources if one supplier fails to deliver. Multisourcing can also increase the quality and

innovation of the products or services, as the company can benefit from the best practices and

capabilities of different suppliers12.

The other options are not correct because:

•A. Single sourcing. This is a supply chain strategy that involves sourcing from a single supplier,

rather than diversifying the supplier base. Single sourcing can reduce the leverage of the company to

reduce costs, as it makes the company dependent on the supplier’s pricing, terms, and performance.

Single sourcing also increases the risk of supply disruptions, as the company has no backup sources if

the supplier fails to deliver. Single sourcing can also limit the quality and innovation of the products

or services, as the company has no access to the variety and expertise of different suppliers12.

•C. Long-term agreement. This is a contractual arrangement between a buyer and a supplier that

specifies the terms and conditions of the supply relationship for a certain period of time. Long-term

agreements can reduce the leverage of the company to reduce costs, as they lock the company into a

fixed price and quantity, and limit the company’s flexibility to adjust to changing market conditions.

Long-term agreements can also reduce the incentive of the supplier to improve the quality and

innovation of the products or services, as the supplier has no competition or threat of losing the

contract3 .

•D. Service-level agreement (SLA). This is a contractual document that defines the expectations and

responsibilities of the buyer and the supplier regarding the quality and performance of the service

provided. SLAs can reduce the leverage of the company to reduce costs, as they may impose

penalties or fees for non-compliance or poor service. SLAs can also increase the complexity and cost

of monitoring and enforcing the service standards, as the company and the supplier need to measure

and report the service outcomes .

Reference := 1 Single Sourcing vs. Multiple Sourcing: Which Is Better?1 2 Single Sourcing vs. Multiple

Sourcing: What’s the Difference?2 3 Long-Term Agreements: What Are They and Why Do They

Matter?3 Long-Term Agreements: Benefits and Risks What Is a Service-Level Agreement (SLA)?

Service-Level Agreement (SLA) - an overview | ScienceDirect Topics

Comments

Question 6

When starting an external benchmarking study, a firm must first:

- A. determine the metrics which will be measured and compared.

- B. identify the target firms with which to benchmark against.

- C. understand its own processes and document performance.

- D. determine its areas of weakness versus the competition's.

Answer:

C

Explanation:

External benchmarking is a strategic tool where a company compares its processes and performance

metrics to industry bests or competitors1. Before starting an external benchmarking study, a firm

must first understand its own processes and document performance, so that it can identify the gaps

and opportunities for improvement. This is also a requirement for regulatory compliance2. Without a

clear understanding of its own processes and performance, a firm cannot effectively benchmark

against others or set realistic goals and strategies. Reference:

•What Is External Benchmarking? (with picture) - Smart Capital Mind

•5 Strategies for Effective ASC External Benchmarking - Becker’s ASC

Comments

Question 7

A disadvantage of a capacity-lagging strategy may be:

- A. lack of capacity to fully meet demand.

- B. risk of excess capacity if demand does not reach forecast.

- C. a high cost of inventories.

- D. planned capital investments occur earlier than needed.

Answer:

A

Explanation:

A capacity-lagging strategy is a conservative approach to capacity planning that involves adding

capacity only when the firm is operating at full capacity because of an increase in demand1. This

strategy can help minimize costs and reduce the risk of excess capacity, but it can also lead to a

disadvantage of not being able to fully meet customer demand if it rises quickly2. This can result in

lost customers, revenue, and market share, as well as lower customer satisfaction and loyalty3.

Reference:

•Lag Capacity Strategy, Lag Demand Strategy - UniversalTeacher.com

•Capacity Planning Strategies: Types, Examples, Pros And Cons - Toggl

•3 types of capacity planning strategies (with examples) - Xola

Comments

Question 8

Which of the following statements is an assumption on which the economic order quantity (EOQ)

model is based?

- A. Customer demand is known but seasonal.

- B. Items are purchased and/or produced continuously and not in batches.

- C. Order preparation costs and inventory-carrying costs are constant and known.

- D. Holding costs, as a percentage of the unit cost, are variable.

Answer:

C

Explanation:

The economic order quantity (EOQ) model is a formula that calculates the optimal order quantity

that minimizes the total inventory costs, such as ordering costs and holding costs. The EOQ model is

based on several assumptions, one of which is that the order preparation costs and inventory-

carrying costs are constant and known. This means that the costs of placing and receiving an order,

and the costs of storing and maintaining the inventory, do not change with the order quantity or the

inventory level, and that they can be estimated accurately12.

The other options are not correct because:

•A. Customer demand is known but seasonal. This is not an assumption of the EOQ model, but

rather a violation of it. The EOQ model assumes that the customer demand is constant and known,

and that the orders are placed at regular intervals. However, if the customer demand is seasonal, it

means that it varies over time and may not be predictable. This can affect the accuracy and

applicability of the EOQ model, as the optimal order quantity may change with the demand

pattern12.

•B. Items are purchased and/or produced continuously and not in batches. This is not an assumption

of the EOQ model, but rather a contradiction of it. The EOQ model assumes that the items are

purchased and/or produced in batches, and that the inventory level decreases gradually until it

reaches zero, at which point a new order is placed and received. However, if the items are purchased

and/or produced continuously, it means that there is no need to place orders or maintain inventory,

and the EOQ model becomes irrelevant12.

•D. Holding costs, as a percentage of the unit cost, are variable. This is not an assumption of the EOQ

model, but rather a complication of it. The EOQ model assumes that the holding costs, as a

percentage of the unit cost, are constant and known. This means that the cost of storing and

maintaining one unit of inventory does not depend on the unit cost of the item, and that it can be

estimated accurately. However, if the holding costs, as a percentage of the unit cost, are variable, it

means that the cost of storing and maintaining one unit of inventory changes with the unit cost of

the item, and that it may not be easy to estimate. This can affect the accuracy and applicability of the

EOQ model, as the optimal order quantity may depend on the unit cost of the item12.

Reference := 1 Economic Order Quantity Model in Inventory Management - Investopedia1 2

Economic Order Quantity: What Does It Mean and Who Is It Important For? - Investopedia2

Comments

Question 9

Information regarding a major new customer is received from sales. The company's most appropriate

initial response would be to adjust the:

- A. production volume.

- B. master production schedule (MPS).

- C. sales and operations plan.

- D. forecast.

Answer:

C

Explanation:

The sales and operations plan (S&OP) is the most appropriate level to adjust when a major new

customer is received from sales. The S&OP is a cross-functional process that aligns the demand and

supply plans with the business strategy and financial goals. It also provides the basis for the master

production schedule (MPS), which is a more detailed and disaggregated plan for specific products or

families. Adjusting the production volume or the forecast would not be sufficient to account for the

impact of the new customer on the overall business objectives and resources. Reference:

•APICS CPIM Part 2 Exam Content Manual, p. 11

•[APICS CPIM Learning System Version 8.0], Module 1, Section A, p. 1-15

Comments

Question 10

Global outsourcing and shared suppliers serving an industry are drivers of which category of risk?

- A. Supply disruptions

- B. Forecast inaccuracy

- C. Procurement problems

- D. Loss of intellectual property

Answer:

D

Explanation:

Global outsourcing and shared suppliers serving an industry are drivers of loss of intellectual

property risk, which is the risk of losing proprietary information or technology to competitors or

other parties. This risk can arise from inadequate protection of data, contracts, patents, or trade

secrets, or from intentional or unintentional disclosure by suppliers or employees. Loss of intellectual

property can result in reduced competitive advantage, lower market share, or legal disputes.

Reference := CPIM Part 2 Exam Content Manual, Version 8.0, ASCM, 2021, p. 11. CPIM Part 2

Learning System, Version 8.0, Module 1, Section A, Topic 4.

Comments

Page 1 out of 56

Viewing questions 1-10 out of 565

page 2